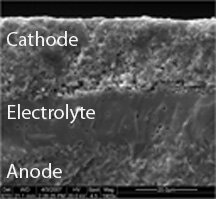

This completed senior design project involves a two-student (Kurt Leopoldt and Clint Myers) team of seniors from the Metallurgical and Materials Engineering Department that developed and characterized fuel-cell fabrication processes at the Colorado Fuel Cell Center. Funded by the CFCC at a level of approximately $5,000, the students have installed and commissioned infrastructure at the CFCC that has enabled the controlled deposition of the critical and sensitive SOFC cathode layer. This layer must be 35 microns thick across a 50 mm SOFC. After installing the fabrication equipment, these students conducted experiments to characterize the effect of fabrication processes on cathode thickness and morphology. In addition to construction of hardware, the students deposited numerous cathode layers, and examined these layers using Scanning-Electron Microscopy available and financed by the MME Department. This team utilized anodes built by another senior design team to make complete cells, and then handed these cells off to a third senior design team for electrochemical-performance testing. Results were directly used in the cell-development efforts currently underway by graduate students at the CFCC.

Solid-oxide fuel cell cathode-development project